The global ammonia market is projected to surpass $110 billion by 2028, driven by its indispensable role in fertilizer production and the growing demand for sustainable energy carriers. Ammonia has long been the backbone of global agriculture, enabling food security for billions of people. However, for over a century, ammonia has been produced at industrial scale using the Haber-Bosch (HB) process, which remains one of the most carbon-intensive industrial activities, contributing significantly to global greenhouse gas emissions. This process relies on high temperature, high pressure, and fossil fuel, only economically viable at large production volumes (>1500 tons/day).

The emergence of green ammonia—produced using renewable feedstocks and carbon-free pathways—offers a transformative solution. By decarbonizing fertilizer supply chains, green ammonia ensures that agriculture can continue to meet rising global food demand while drastically reducing its environmental footprint. Its adoption is becoming urgent, as the agriculture industry faces mounting pressure to cut emissions, enhance sustainability, and align with net-zero targets by 2050. Green ammonia not only secures the future of food production but also establishes agriculture as a key player in the clean energy transition

As the hydrogen economy is rapidly gaining momentum, with the global hydrogen fuel market projected to exceed $1.4 trillion by 2050, ammonia plays a critical role, serving as the safest and most efficient hydrogen carrier. With its high hydrogen density and low fire hazard, ammonia offers superior safety and efficiency for global hydrogen distribution.

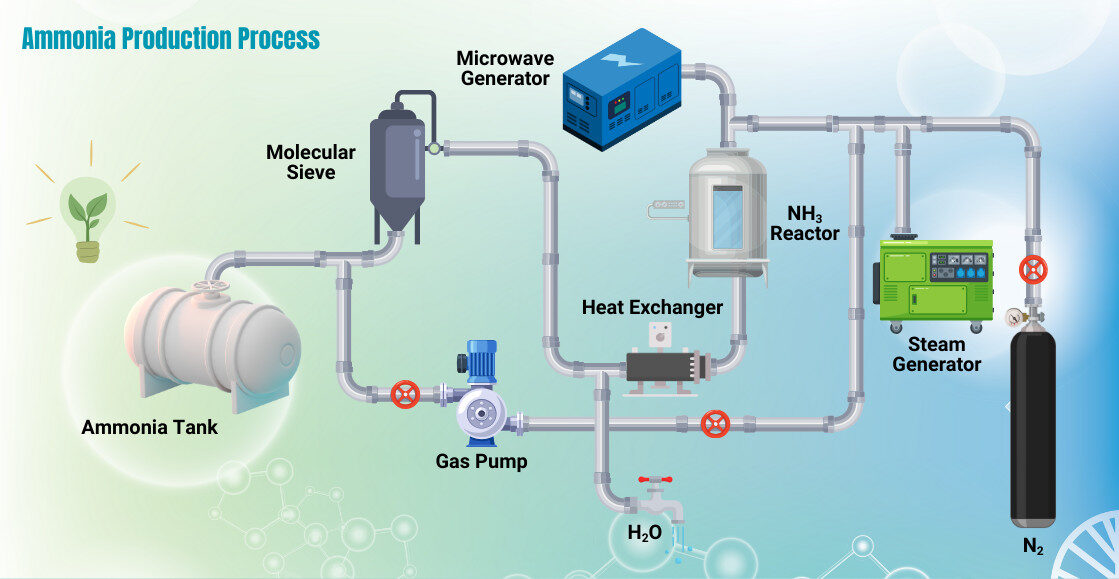

Our proprietary electrodeless plasma technology changes the way ammonia can be made. Instead of relying on expensive, high-pressure systems, it works safely at normal air pressure. The system uses plasma to split steam and create hydrogen, which then combines with nitrogen to form ammonia with the help of a catalyst. Powered by an efficient solid-state system, it is designed to be stable, scalable, and energy-efficient. In the future, this process could even achieve net-negative carbon emissions by turning part of the output into urea, a valuable product for agriculture.